Fastplav bitumen melting plant – innovation to reduce production costs

Bitumen melting plants are designed to heat up the material which is transported in solid state. Usually it is transported in packs of various volume and type – 200 l steel barrels, big bags, 25 kg briquettes, etc.). Melting plants of various capacities have been developed for many years for the needs of companies and bitumen facilities. Their operating principles are similar, but none of them satisfied the required output for products of any solidity with the quality and properties of the material being preserved.

HOW THE FASTPLAV MELTING PLANT WAS CREATED

BitumTech specialists set a goal to put into action the operating principle of bitumen preparation which implies keeping the material in heated state for no more than three hours. Thus, the process of burnoff of asphaltenic substances in the material, i.e. bitumen aging and significant deterioration of the quality of road pavement or construction materials, is excluded.

None of the existing bitumen melting plants satisfied the requirements of the newly developed technology. That is why BitumTech specialists took on development of the in-house melting plant model. As a result, the innovative melting plant FastPlav was created.

In the course of work several designs were worked out until the team achieved the target figures. In the beginning a device with the system of electric heating of the material was manufactured, however operation-wise it was unreasonably costly. So, the company specialists faced another challenge – to cut the cost of the process as much as practical with preservation of the device’s efficiency.

After that a number of designs of bitumen melting plants based on the oil heating system were developed and served basis of a production sample. The process was not easy: one of the main problems was the matter of creation of the upper V-type cutting heating coil. Such pipes are not manufactured commercially, that is why the designers manufactured them by themselves.

ABOUT THE ADVANTAGES OF THE FASTPLAV BITUMEN MELTING PLANT

Besides simple design and ease of use the bitumen melting plant has a number of advantages allowing to reduce manufacturing and temporary costs of the facility.

The highlight of the model is the unique design of the cutting heating coil and arrangement of heating coils in a way ensuring quick displacement of the cut bitumen brick to the bottom part. The whole brick is quickly put into operation thus accelerating the melting process. The model uses coil heaters, i.e. oil heaters through which hot oil with the heating-up temperature of 180°С is circulating.

One of the advantages of the processing line with its key element being the FastPlav bitumen melting plant is the period of heat treatment which does not exceed three hours up to the full use of bitumen (for preparation of asphalt-concrete mixes), therefore bitumen is not overheated. Thus, degradation of its properties is not possible. The technology includes stable elements, which implies reduction of the processing time, of product evaporation, of the quantity of burnt fuel and therefore of the manufacturing costs of the process of bitumen melting and heating.

Due to reduction of the production area and cutdown of heat emission the technology-related impact on the environment is decreasing which is of particular importance given the present-day environmental situation. The need for the facility to operate at night time is eliminated, which, in its turn, causes dramatical mitigation of the danger of accidents caused by human errors and reduction of equipment’s wear and tear and maintenance costs.

DESIGN OF THE FASTPLAV BITUMEN MELTING PLANT

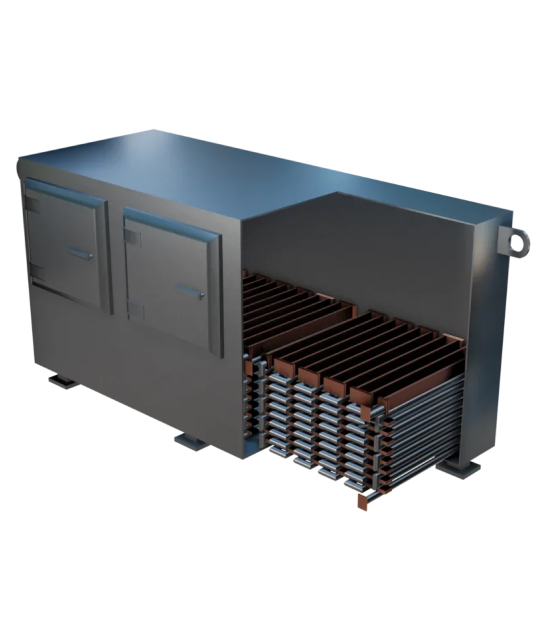

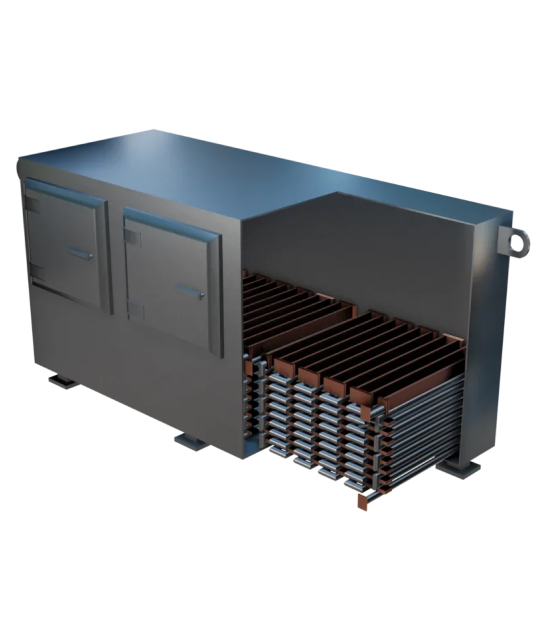

The bitumen melting plant which was created and patented by BitumTech specialists is a storage tank with thermal insulation and loading chambers which receive packaged bitumen (in containers such as Clovertainer, Rubitainer, etc.). Loading is done with the help of a fork lifter or with the use of an electric hoist supplied with the bitumen melting plant (this method is preferable for loading of the material in such packages as big bags, polycubes, etc.). Loading may be both side and overloading (depending on the type of packaging). The process of melting occurs due to heating of bitumen by hot oil fed to heating coils. The volume of the heated material may be formed depending on the demand of the bitumen facility.

The design is modular and is meant to ensure any required output. Guaranteed output is attained due to the unique innovative system allowing to reduce the melting time by 1.25-1.7 as compared to national and foreign analogues. The offered melting plants may be used as equipment of transshipment terminals and bitumen terminals. In this event the temperature of road bitumen melting is optimal for its further use.

Overall dimensions of the FastPlav bitumen melting plant are not large allowing to successfully use this bitumen production equipment for mobile asphalt-mixing plants easily moving them around the facility area and beyond. For comparison, conventional equipment of asphalt-mixing plants has overall dimensions eight times bigger than those of the FastPlav. While the use of this plant will significantly reduce energy costs for compensation of heat loss emitted to the environment.

The operating principle of bitumen heating equipment

The patented technology implies quick displacement of the material from the loading chamber to the storage tank where due to the developed surface of heating elements bitumen is quickly heated up to the required temperature. Other conditions (characteristics of thermal protection of equipment, capacity of the heating system, heat-release surface area and temperature of heating elements) being equal, decrease in the bitumen volume at each processing stage ensures reduction of preparation time and this is an obvious advantage of this solution as compared with conventional melting plants.

Packed bitumen, freed from package or without a bottom cover, is loaded into the feed chamber of the bitumen melting plant. Then unpacking and melting of bitumen occur as it lowers down the bottom part of the melting plant (storage cavity). Heating up to the pumping-out temperature is done trough heating coils with circulating hot oil. As soon as the set temperature is achieved bitumen is pumped out to the process flow, empty package is removed from the feed chamber and the next batch of packed bitumen is loaded.

Just-in-Тime operation

All the BitumTech products are based on the concept of careful production management. The FastPlav bitumen melting plant is no exception.

The Just-in-Time method of efficient industrial engineering implies that the materials needed for the manufacturing process are found in the needed quantity just in the needed time.

The company respecting this principle in its operations will minimize downtimes, make efficient use of the facility area without creating unnecessary storage facilities, receive materials without defects and reduce duration of the production cycle. All these premises exert favourable impact on yield increase of the company with minimal cost.

The FastPlav resource-saving technology of packed bitumen preparation is an up-to-date and efficient approach to initial heating and further melting of bitumens. The patented technology ensures quick heating of the material for asphalt-mixing plants, thus improving the output. The primary objective of the bitumen melting plant is to melt the material located in solid state in clovertainers or big bags. Meanwhile it is extremely important to avoid intrusion of package parts into bitumen.

Fields of application

Plants for melting and initial heating of road bitumen up to the optimal temperature (bitumen melting plants) are becoming more and more popular due to emergence of innovative bitumen package. These melting plants are applied in the construction field for manufacturing of asphalt-concrete mixes, bituminous felt and other materials for repair and construction of buildings, oil and gas industry. The appeal of the plant is ensured also by the possibility of transportation of bitumen in similar packages by any vehicles over all distances, flexibility of production due to heating-up of the needed batch of bitumen only, lack of demand for complicated expensive equipment, etc. Output of the manufactured plants is from 3 t/h.

The design of OOO Energy-Efficient Butumen Technologies allows to save production resources of the facility and find efficient solutions to the problems of reduction of environmental pollution. Thermotechnical characteristics are in accordance with the scheduled time of melting and heating.