Мы получили заявку и перезвоним вам в бижайщее время

Main tasks

-

Development of the energy-efficient technology for reception, storage and heating of bitumen

-

Energy costs calculation

-

Development of the materials and equipment specification

Decision

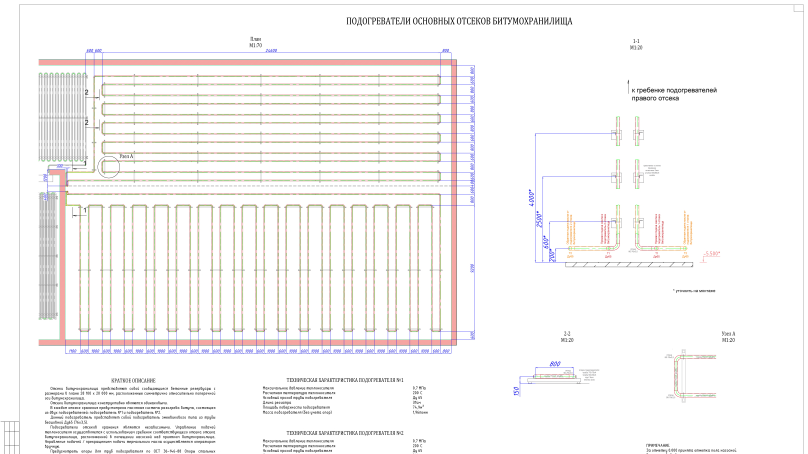

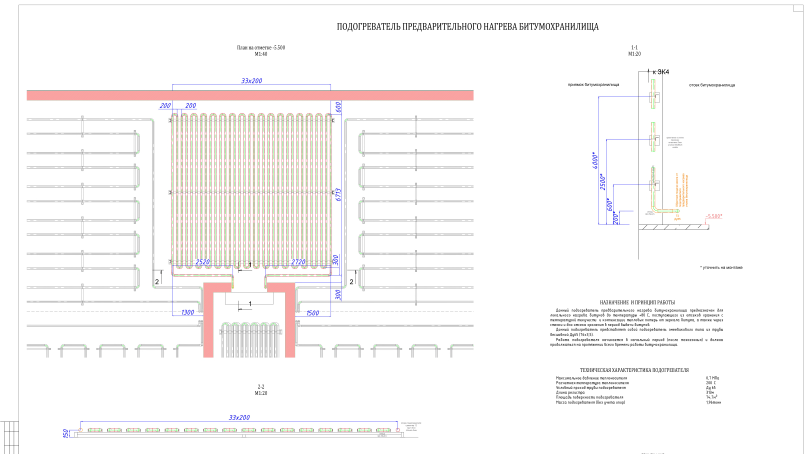

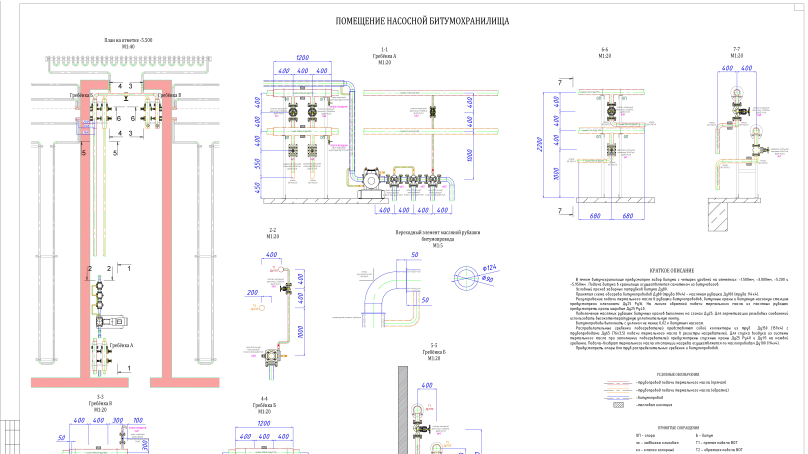

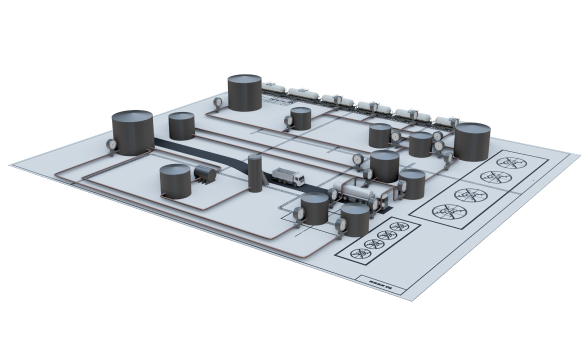

The pit-type bitumen storage facility consists of two bays with the total nominal volume of 6,600 sq.m. Within the framework of the engineering design the optimal layout for heating elements was selected. The technology implies preliminary heating in the storage bay to the pour point and in the catch pit discharge area – by a group of preliminary heaters. The special structure of discharge ensures inflow of the most heated bitumen from storage bays to the discharge pit while the bitumen is discharged with the operational temperature. The key feature of this storage tank is that the operation line does not provide for day tanks, and the bitumen is discharged from the pit straight to bitumen trucks. It was made possible due to the special structure of the pit discharge and the special arrangement of heating elements and intake manifolds.

Results

-

Engineering design of the pit-type railway bitumen terminal was worked out

-

Specification of equipment and materials was developed