Мы получили заявку и перезвоним вам в бижайщее время

Main tasks

-

Development of the efficient technology for reception, storage and heating of bitumen

-

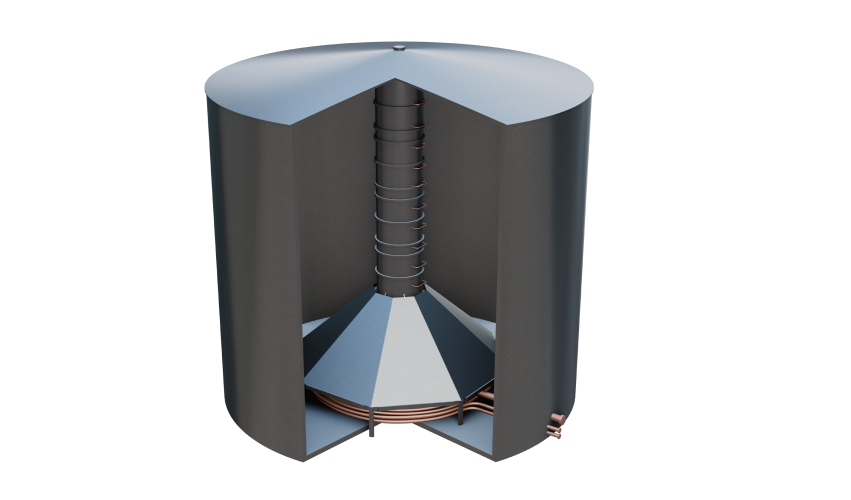

Development of the design of the internal heating unit for the vertical steel storage tanks RVS 3000

Decision

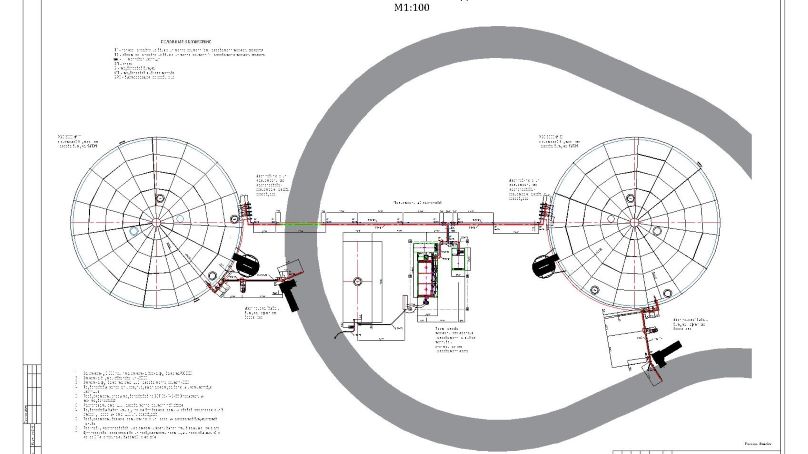

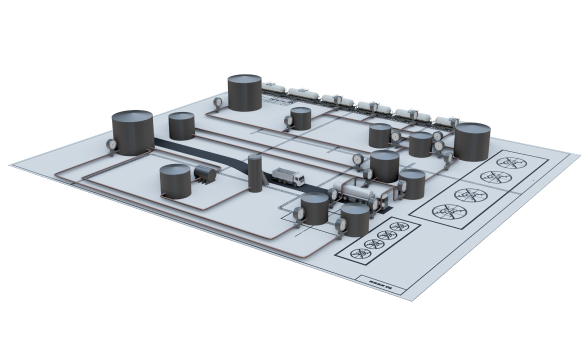

The bitumen storage facility includes two vertical steel storage tanks RVS 3000. In accordance with the engineering design energy costs calculation of the storage’s heat demand was done, a heating station for high-temperature organic heat transfer agents was selected, technologies for reception and discharge of bitumen onto external vehicles were developed. The main requirements of the customer were to preserve qualitative characteristics of bitumen and to minimize energy costs during heating of bitumen and reception and discharge of binders. Therefore, a combined system of oil heating of bitumen and transportation lines was suggested: an electric oil heater and a flame oil heater. Under technical upgrade the vertical steel storage tanks RVS 3000 will have t

he KUPOL systems of internal bitumen heating installed with the output of 100 t/day each.

The main and the auxiliary process equipment were selected, the process flow diagram was developed, the communication lines were designed taking into account execution of all the operations with minimal costs.

Results

-

Engineering design of the 6,000 t bitumen storage facility (2×vertical steel storage tank RVS3000)

-

Detailed design of the Kupol-100-3000 system of internal bitumen heating